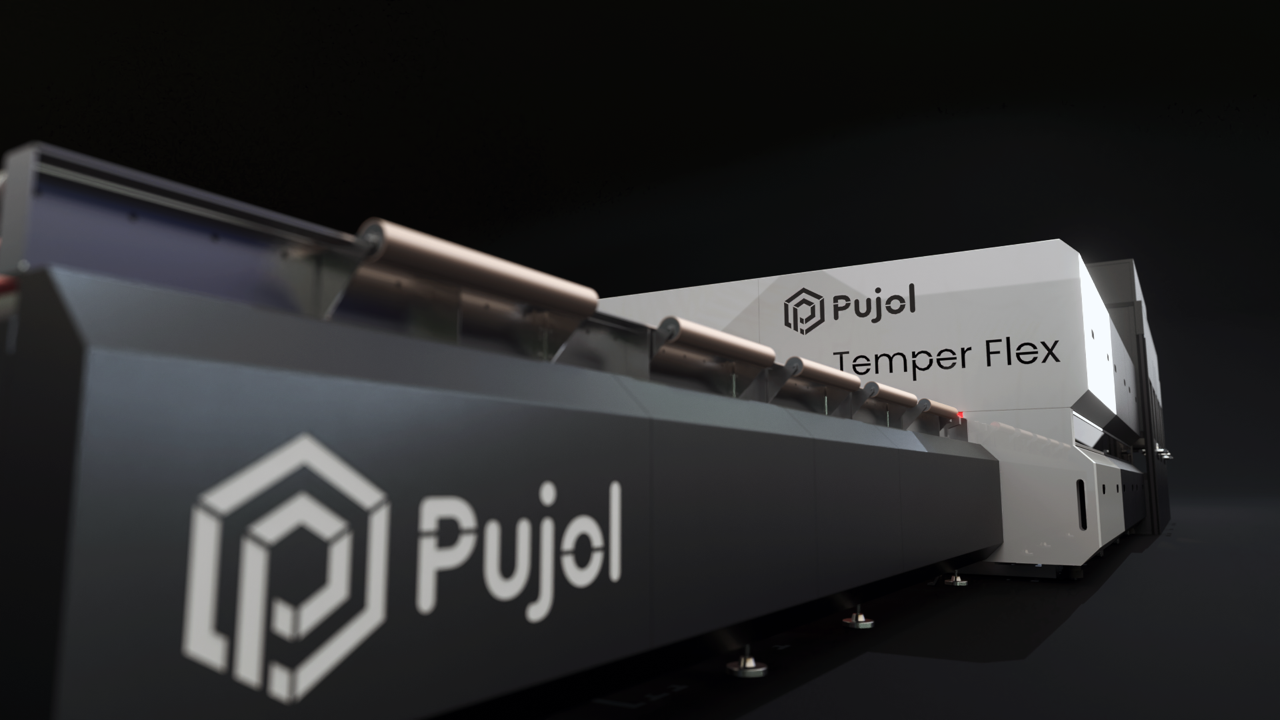

TEMPER FLEX. New Pujol tempering oven.

In our more than 110-year history, we have built our reputation in the thermal engineering industry by continuously demonstrating high adaptability and innovation in top-type furnace manufacturing. In the glass sector we stand out, until now, for our reputation in the manufacture of ovens and integral systems for glass lamination, glass bending and systems Heat Soak Test

We once again display this unique capacity for adaptation and continuous innovation, and a few months after the acquisition of the glass division of the Italian company TEKNOKILNS, we announce the launching of our new TEMPER FLEX, oven, a unique and innovative for glass tempering solution developed on the technological basis and long experience of TEKNOKILNS Engineering, the new TEMPER FLEX oven, covers the needs that today demand the glass professionals in terms of their global vision of the business and related to the importance of maintain the lowest possible energy costs on a continuous basis, the achievement of a perfect optical quality of the final products and all this combined at the same time with its daily challenges in terms of flexibility both of products that are increasingly technical and complicated to process such as soft and selective coating glasses and well as adaptability to a demand that is completely unstable and fluctuating.

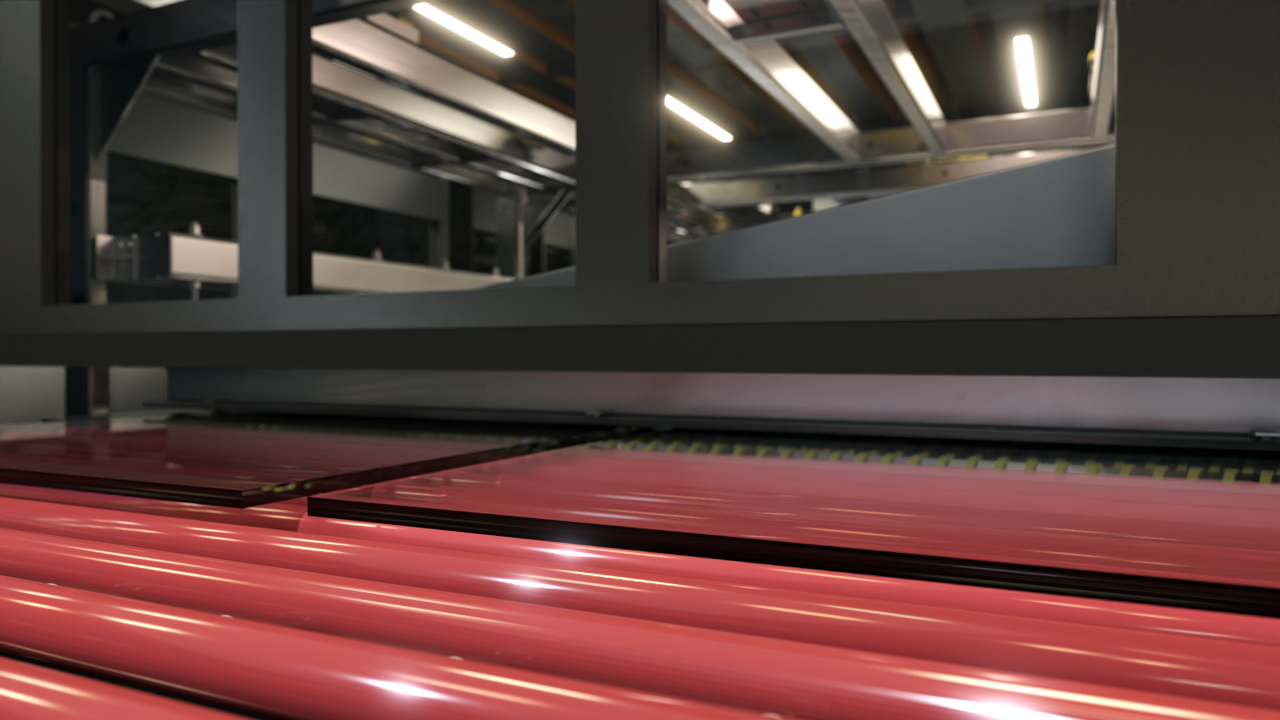

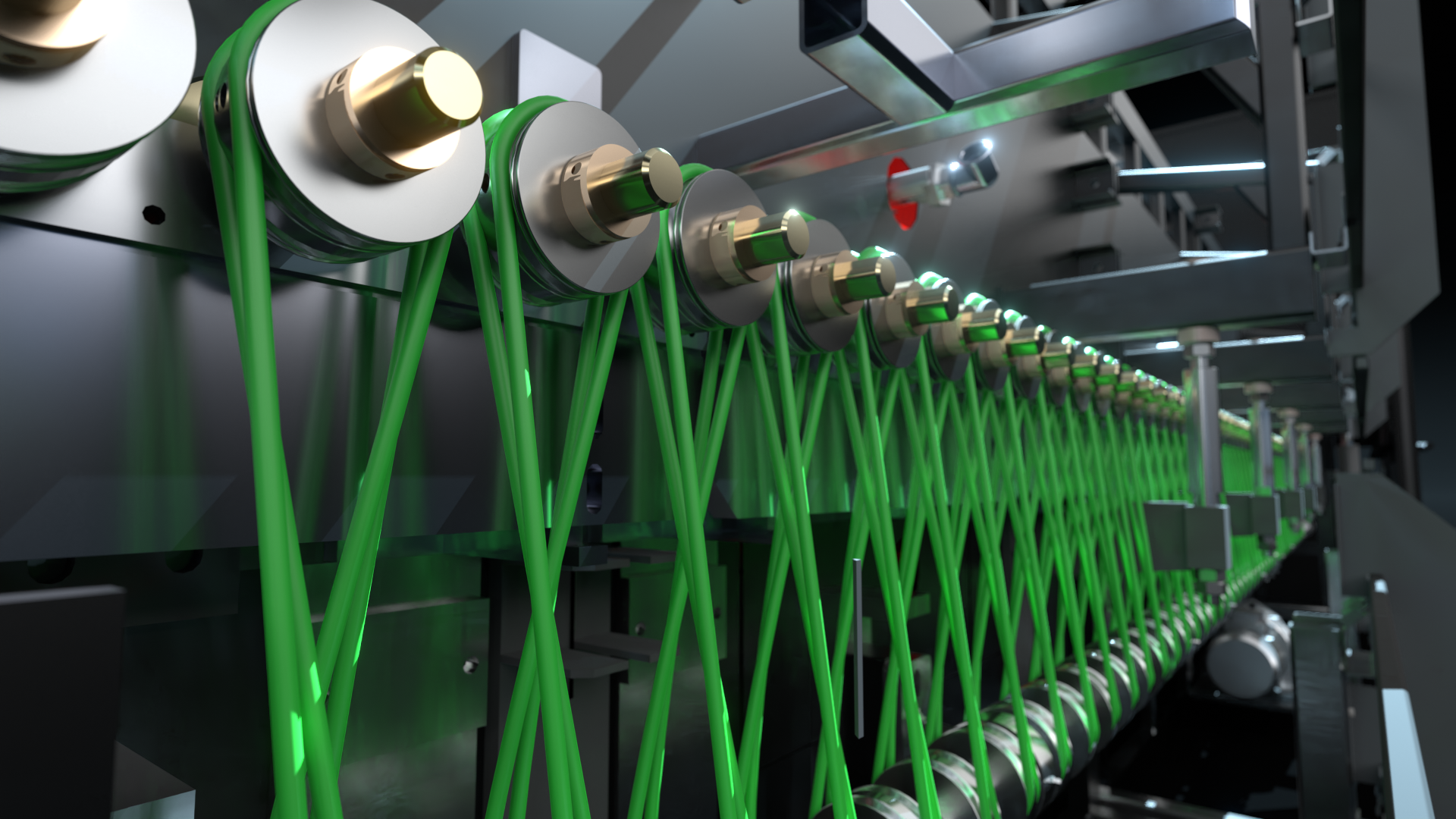

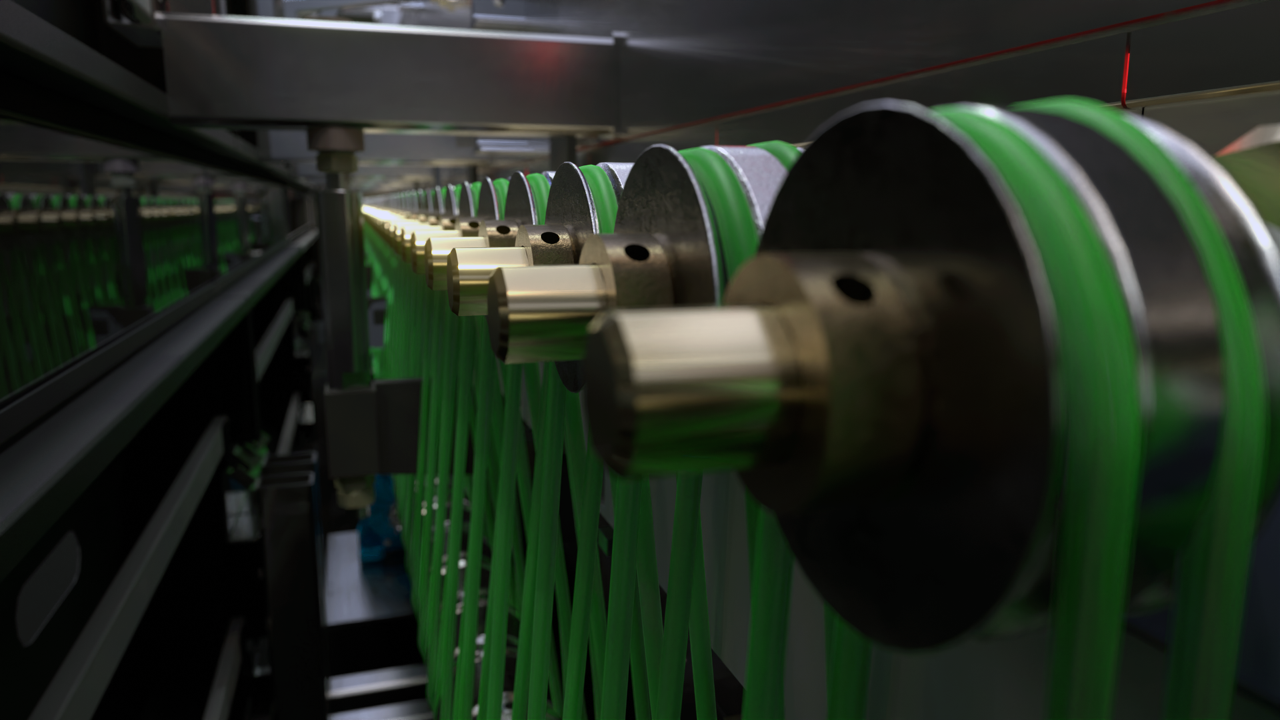

TEMPER FLEX, stands out for its high thermal efficiency and low energy consumption. This is, first, thanks to the fact that advanced engineering has been worked on in-depth that allows the heating chamber to have a higher degree of insulation but with half the thickness of the other manufacturers and models on the market, this is due to the use of High-TECH materials, not yet widely introduced in the traditional industry, but very present in other areas such as aerospace industry, this reduction in total thickness results in that TEMPER FLEX ovens can be equipped with rollers with a smaller diameter than any equivalent on the market, and therefore by reducing the pitch between axes, being able to offer a planimetry superior to any comparison. In the second place, in terms of the design of the Thermal-Heating Systems set, it is worth noting how an advanced system of high-performance matrix panels has been incorporated in the upper part which, together with the integrated design of the resistances, provides both high thermal efficiency by use a high diameter KANTHAL rod with a high power W/cm2 which offers a high transfer and heating speed, but above all because this engineering and unique design prevents mechanical deformation of the resistances, offering a useful life of the heating equipment than 12 years, and offering PUJOL, a 5-year Warranty on its heating equipment, a fact that no other manufacturer on the market is capable of matching at this time. Regarding the lower heating solution, contrary to other solutions on the market that use metal floors, TEMPER FLEX, equips a singular and unique solution on the market that makes it totally innovative and disruptive; but which has been working in the market with spectacular results for more than 5 years in the hands of TEKNOKILNS Engineering. The lower heating system of the chamber is designed and equipped with a system of ceramic modules with embedded resistances of high density and thermal transfer as well as high mechanical resistance with a final layer of a non-stick coating of the glass that helps to transmit uniformly the heat on the rollers and the glass, this is a solution with lower energy consumption and greater speed and energy efficiency than the traditional systems of protection of inferior resistances based on metal sheets on the screed. And that offers both lower energy consumption and lower maintenance costs in the long run, both in terms of sheet replacement and cleaning maintenance times when there is a break in the oven.

The final optical quality of the glasses is another of the differential facts of TEMPER FLEX, versus other solutions, especially in oven solutions with widths greater than 2.2 m. and the answer is in the distance between the rollers inside the heating chamber of the oven. As indicated, TEMPER FLEX, uses unique thermal insulation solutions that allow the use of smaller diameter rollers than the industry standard today, consequently, with a smaller diameter of rollers, a smaller distance between them, and a greater number of support rollers, it avoids distortion. optics or minimizes it to levels unmatched by other configurations.

Optionally and as a reinforcement to the radiation system mounted as standard, in the TEMPER FLEX- IR models, the oven can be configured with the inclusion of a high-efficiency convection system based on the blowing of preheated air at 500ºC inside the chamber. of heating, this system, which is the one that incorporates the TEMPER FLEX–PROCONV Series, provides greater flexibility, speed, and quality and allows the tempering of all types of layered glass, low emissive, selective, and coefficient 0.01.

Throughout the tempering process, TEMPER FLEX, takes maximum care of the quality of the finished product, and its possible effects on the final quality of the product obtained. Consequently, a deep effort has also been made to optimize highly elaborate engineering in the tempering section, equipping it with an efficient sectional ventilation system that helps both to reduce the generation of anisotropies in the glass and to increase and maintain optimal planimetry, especially in glass with length greater than 2.5 m. Besides, thanks to this technical solution, TEMPER FLEX, allows the use of a single turbine to complete the tempering process more efficiently and with a higher quality of planimetry, giving as an added benefit that it is possible to reduce the total length of the oven and, above all, reduce costs both in the contracted electrical power needs and in the cost of the electrical installation by installing Alternating Current motors that offer lower maintenance costs than direct current motors offered by other manufacturers.

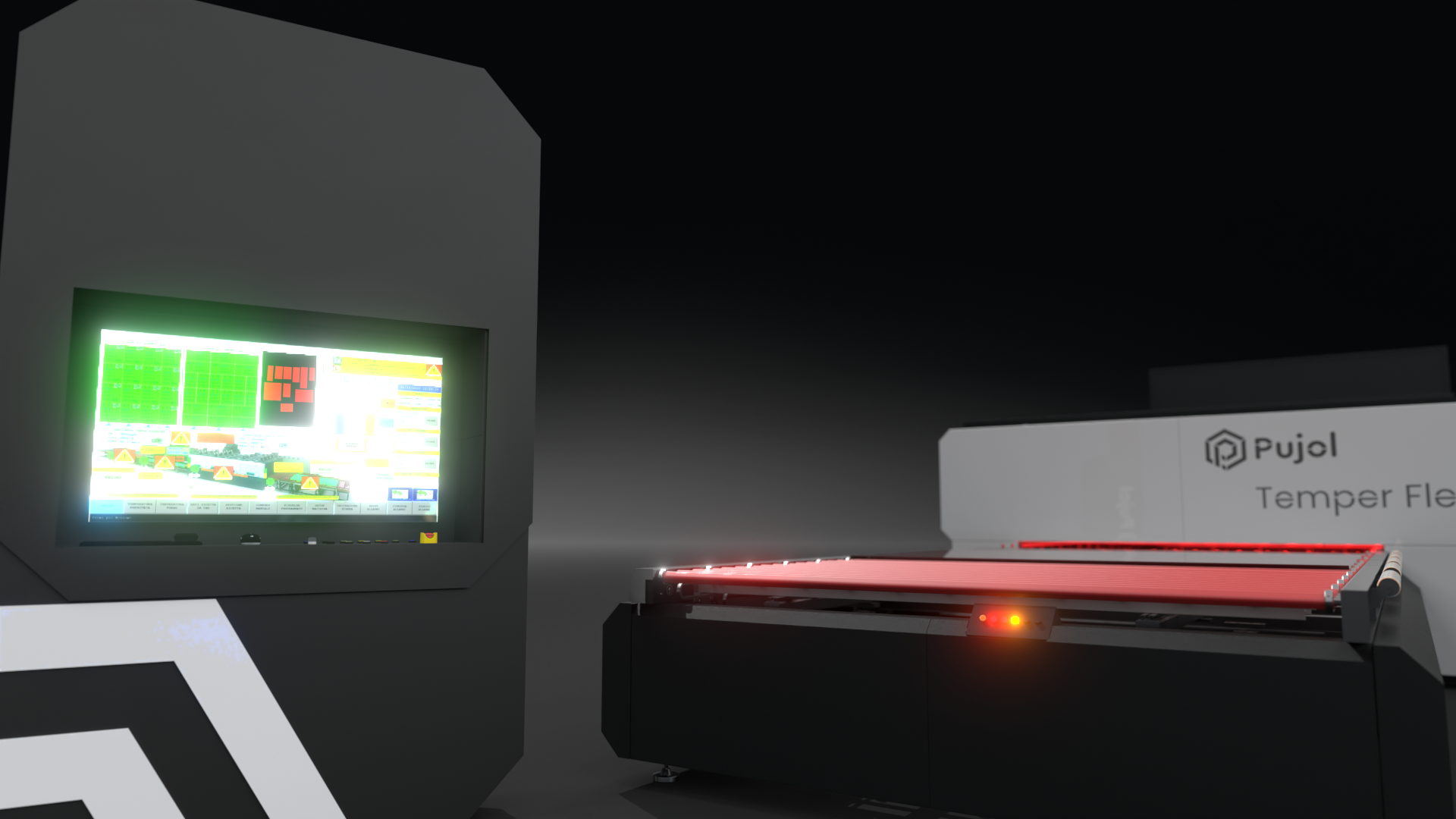

Regarding the solution of Regulation and Control of the process. TEMPER FLEX, it’s equipped with easy and intuitive programming and uses a supervision system that facilitates process management for the oven operator. Through a large 55” screen, the temperature of all sections of the oven is controlled and the thermal profile of its interior is defined, the temperatures of the glass are through a scanner on the surface of the glass when it leaves the oven. and access to the registration and storage of process data, which allows the operator to track each finished workload, as well as create their Recipe Base based on the different types of new glass that are being processed and the load provisions.

Besides, TEMPER FLEX, incorporates the PUJOL e-Connect system as standard, which allows remote and secure process traceability, as well as remote assistance and production control.

In summary, TEMPER FLEX is a solution that offers:

1.-Low production cost.

2.- Low maintenance.

3.-High Quality of tempered products.

4.- High Production flexibility.